Form-Shifting, Self-Therapeutic Machines Are Amongst Us

Form-changing machines have lengthy been a staple of science fiction—for good cause. Contemplate the ability of the villainous killing machine within the 1991 movie Terminator 2: Judgment Day. When the liquid-metal T-1000 arrives, the heroes rapidly understand they’ve two massive issues: First, their foe can morph, turning human-looking appendages into lethal blades. Second, blowing holes within the machine barely slows it down; it may heal itself!

Self-healing machines are amongst us already. After all, the truth doesn’t fairly match as much as the T-1000, however scientists have discovered that the fictional machine’s two capabilities are intently associated. “The elemental science that provides rise to self-healing supplies is similar habits that enables them to alter form,” says Zhenan Bao, a chemical engineer at Stanford College. And in latest months, scientists have developed a brand new number of supplies with the skills to heal and shift their form—amongst different abilities. The researchers have used these substances to assemble new forms of electronics with functions in robotics, bioelectronic interfaces, wearable gadgets and superior shows. These machines is also extra environmentally pleasant than these created from conventional supplies similar to silicon and metallic.

The science of self-healing supplies goes again virtually two centuries, nevertheless it actually took off within the Seventies. That’s when researchers started learning the self-healing potential of polymers—massive molecules consisting of repeated elements, the way in which a sequence is made up of hyperlinks. The composition of a molecule’s primary polymer chain, or “spine,” determines a spread of properties, together with the molecule’s toughness or elasticity. Some healable polymers require a set off, similar to publicity to a selected temperature, gentle or strain, to reknit their damaged bonds. Others heal spontaneously. These “dynamic” polymers use weaker molecular bonds than these in most steady molecules. For example, many dynamic supplies are held along with hydrogen bonds, by which positively charged hydrogen atoms appeal to different, negatively charged atoms. “What’s good about hydrogen bonds is it’s spontaneous,” says Carmel Majidi, a mechanical engineer at Carnegie Mellon College. “You do not have to soften or warmth the supplies; they only kind these bonds upon contact.”

Weak bonds give such supplies fascinating properties. “It seems like a stable. And when you stretch it in a short time, it breaks like a stable. However when you maintain it, it drips like a liquid,” Bao says. “The molecules will not be fastened in place, so these polymer networks are constantly forming and dissociating.” This promiscuity is what permits for self-healing. “After we injury the fabric, the bonds break. However while you put the items collectively, these hydrogen bonds kind very readily, and the fabric recovers its mechanical properties,” Bao says.

The identical precept underlies stretchable electronics. “These dynamic bonds enable us to stretch the fabric to a number of hundred instances its authentic measurement as a result of the bonds can break and reform,” Bao says. Utilizing a number of forms of bonds, with totally different strengths, produces supplies which are each pliable and hard.

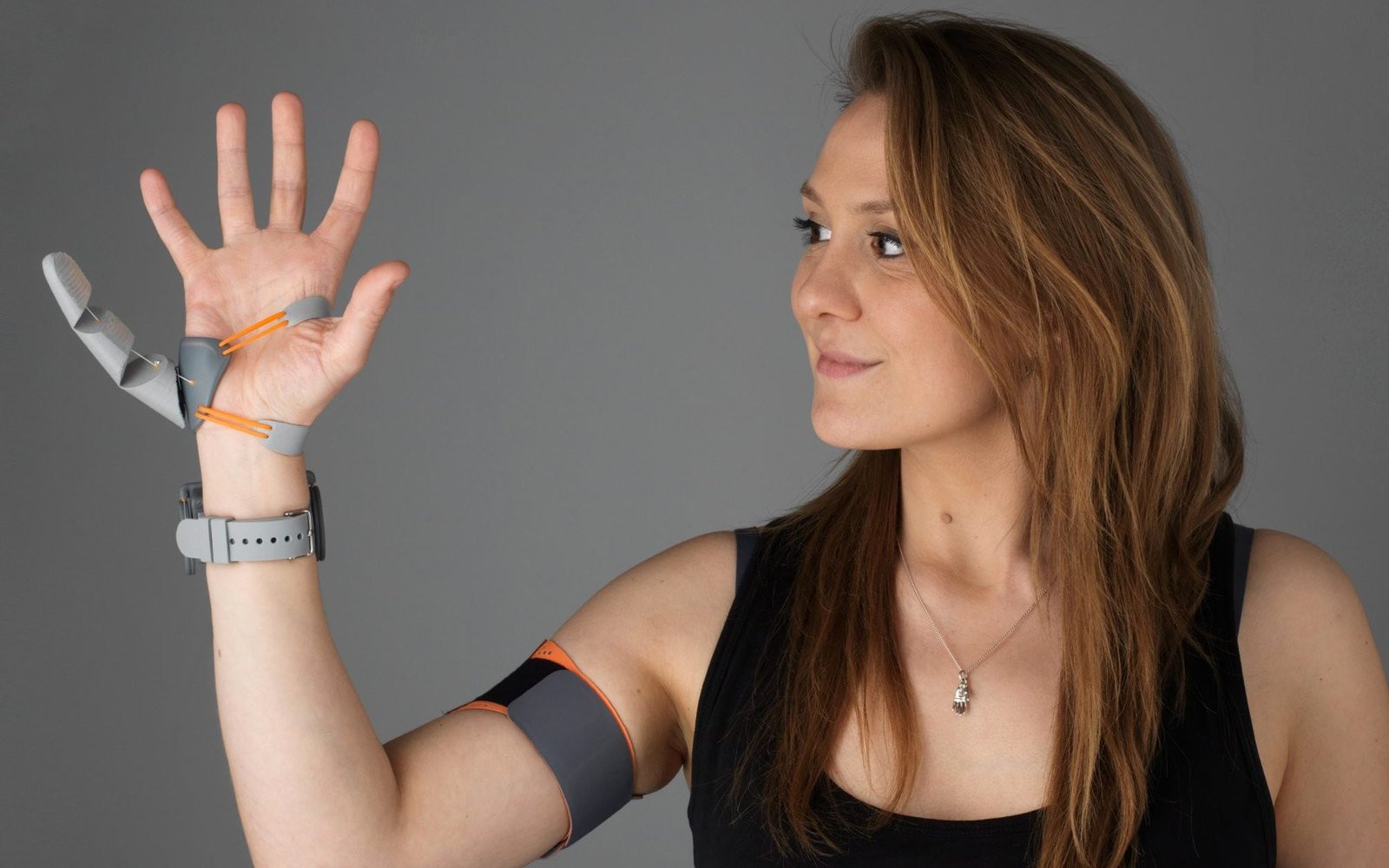

Supplies want different properties to be used in electronics, although. First, they should be good conductors. Most polymers are insulators, nonetheless. One resolution is so as to add metallic particles, nanowires or carbon nanotubes to a polymer with a view to make the stretchable materials conductive. Bao and her colleagues have used such approaches to assemble self-healing “digital skins” that conform to the physique and are able to sensing strain and pressure and measuring coronary heart charge.

One other resolution is liquid metals. In a examine revealed earlier this 12 months, Majidi and his colleagues launched liquid-alloy microdroplets right into a polymer gel dotted with silver flakes. The ensuing materials was stretchable, self-healing and conductive sufficient to energy the motor of a gentle robotic. “The last word purpose is to construct digital and robotic methods that embody all of the properties of organic tissues,” Majidi says, “not only for performance but additionally resilience and self-healing.”

These adaptive supplies are easy conductors. Researchers are additionally growing equally stretchy supplies with different digital properties. They embrace semiconductors by which conductivity will increase with temperature, in addition to dielectrics, that are insulators that change their cost properties, or “polarize,” in electrical fields. Researchers have efficiently mixed these totally different supplies to make healable transistors, capacitors and different digital parts. “There’s all types of fabric performance that might be helpful in gentle robotics or wearable electronics,” Majidi says. “We work with thermoelectrics for changing warmth into electrical energy, so it could be nice to have a thermoelectric garment that might get well its energy-harvesting capabilities if it’s broken.” Discovering such real-world functions is Majidi’s present focus. “Now that we’ve overcome loads of the bottlenecks, that’s the subsequent massive step,” he says.

Benjamin Tee, an engineer on the Nationwide College of Singapore, thinks self-healing electronics shall be a boon for the surroundings. “Self-repair has loads of implications for lowering digital waste,” he says. “Is there a future the place when you drop your telephone, it may restore itself?” In a examine revealed in 2020, Tee and his colleagues developed a stretchy, clear dielectric materials to be used in light-emitting capacitors. They employed this materials to assemble a tool able to producing vivid illumination with a lot much less energy than earlier stretchable optoelectronics required. In consequence, it was longer-lived and safer to be used in human-machine interfaces. It additionally self-healed after injury. “It could get well near one hundred pc of its authentic brightness,” Tee says. The workforce demonstrated the machine in a gentle robotic gripper that sensed objects in darkness by detecting mirrored gentle. Different potential functions embrace near-invulnerable versatile screens, wearable gadgets, and extra.

In time, extra parts will purchase self-healing capabilities. “The holy grail is having a complete digital system that may self-repair,” Tee says. This imaginative and prescient comes nearer to the T-1000, however a serious barrier is that advanced electronics require a number of layers. When such gadgets are broken, the layers typically now not line up, inflicting circuits to malfunction.

In a examine revealed this spring, Bao and her colleagues offered a possible resolution to this drawback. They used two totally different polymers which have backbones that don’t combine but additionally equivalent hydrogen bonds that allow the layers to cling collectively. “They don’t like to combine, like oil and water,” Bao says. “However now we have molecules on both sides that enable them to stay collectively on the interface.” The researchers stacked 11 alternating layers, creating a movie 70 microns thick (barely greater than half the thickness of a greenback invoice). To check its talents, they lower the movie in half, inflicting the layers to misalign. They then heated the fabric to 70 levels Celsius, and the layers realigned by themselves.

The workforce demonstrated the approach in a self-realigning strain sensor and a gentle robotic whose parts had been roughly assembled magnetically after which microscopically aligned by heating. The researchers haven’t but demonstrated it in advanced electronics—however the examine brings that utility nearer. Group members are already engaged on totally different purposeful supplies, thinner layers and extra advanced layered buildings, Bao says.

As typically occurs, science fiction is slowly turning into actuality. However hopefully the shape-shifting, self-healing machines of tomorrow shall be much less aggressive than the T-1000.